Hydrophobic coating

Working with Imperial College, UPM Kymenne and Aylesford Newsprint this EPSRC Case studentship developed novel lightweight fillers using paper sludge ash and glass cullet which can be used for thermal and acoustic insulation. Imperial research also found that PSA could be converted to a super hydrophobic coating. Our new research is ambitious and seeks to investigate the potential of super-hydrophobic coatings to reduce drag within water transmission pipes.

Low-energy water transmission in pipe lines by hydrophobic coatings

The project aims to investigate the potential of super-hydrophobic surfaces for use in the transmission of fluids over large distances, particularly the potential of a new super-hydrophobic material that has been recently developed from a waste material generated by the paper recycling industry.

Background

The UK water industry uses approximately 4,000 GWh annually to supply fresh water, which accounts for about 3% of the total electricity consumption of the country and costs some £200 million. This energy consumption also causes several million tonnes of greenhouse gasses (GHG) emissions to the atmosphere: in 2007/2008, the UK water industry emitted 5 million tonnes of GHG, of which at least 50% of this is exclusively associated with water pumping. The aim of this project is to make use of sophisticated coatings to develop next-generation pipe surfaces which have 1) considerable less drag than conventional surfaces; 2) a self-cleansing ability and inhibition of bacterial growth.

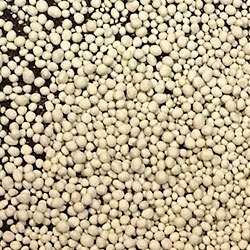

A super-hydrophobic material from a waste generated by the paper recycling industry has recently been developed at Imperial. This material will be applied to surfaces with a texture to trap tiny air pockets. The air acts like a lubricant allowing water to be transported with much lower energy losses. The project will be both experimental and numerical, testing the energy-efficiency and durability of the method and has potential for significant innovation.